Quilt Rotary Screw Air Compressor With Dryer & Tank

for Laser Cutting Machine

Screw Air Compressor with Dryer Package

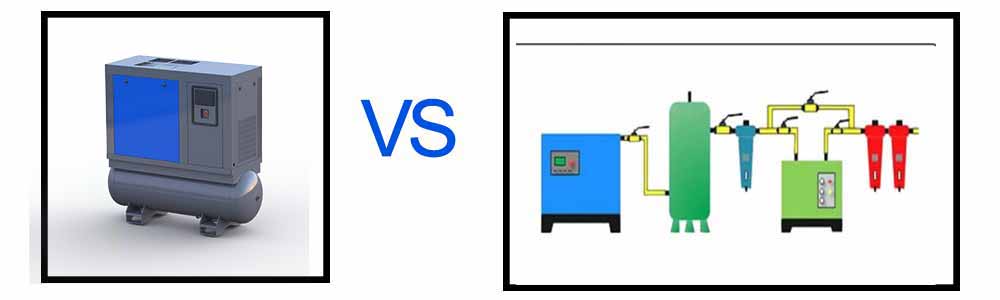

This integrated compressor is all in one series compressed air systerm. it integrates everything you need for an air system. it consists of a variable speed screw air compressor (vsd), a refrigerated air dryer, an air receiver tank, Precise Filters, Auto Drains, and Pipes into one assembly.

We have a normal pressure type and 16 bar integrated compressor for laser cutting machine.

Desiccant Air dryer especially designed for laser cutter air compressor, the pressure dew point is as low as -20℃ and more

Five level high-efficiency precision filter to obtain pure compressed air without oil and water mist

Stainless steel pipelines are used for treatment to avoid secondary pollution

The main oil pipe is connected by a flexible pipeline, which effectively reduces vibration and noise, and runs Noise<70db

Permanent magnet frequency conversion can better control the oil temperature and avoid milk centralized , keep the customer’s site clean