Two Stage Air Compressor VSD Compressor & Permanant Motor-Compmax

What is a two stage compressor?

How does a two stage compressor work?

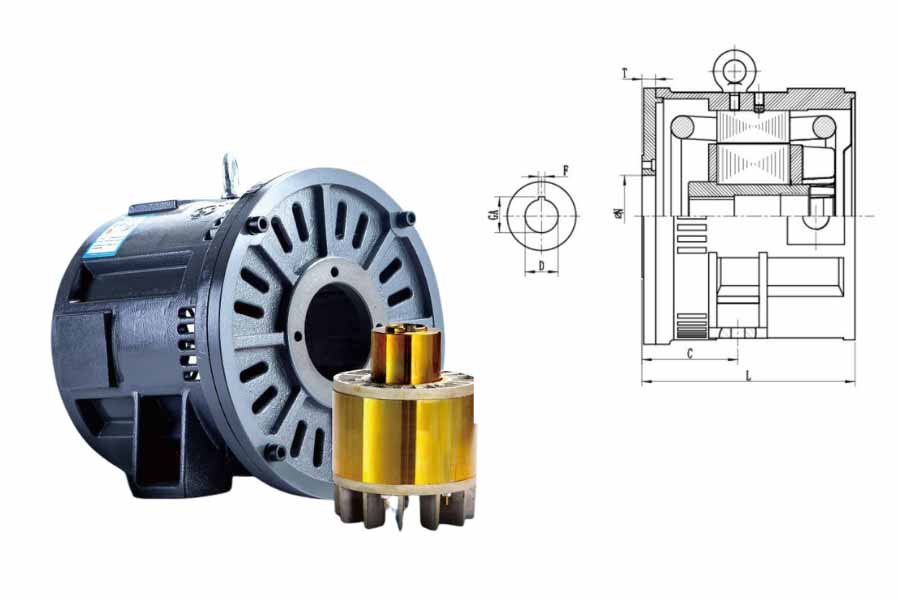

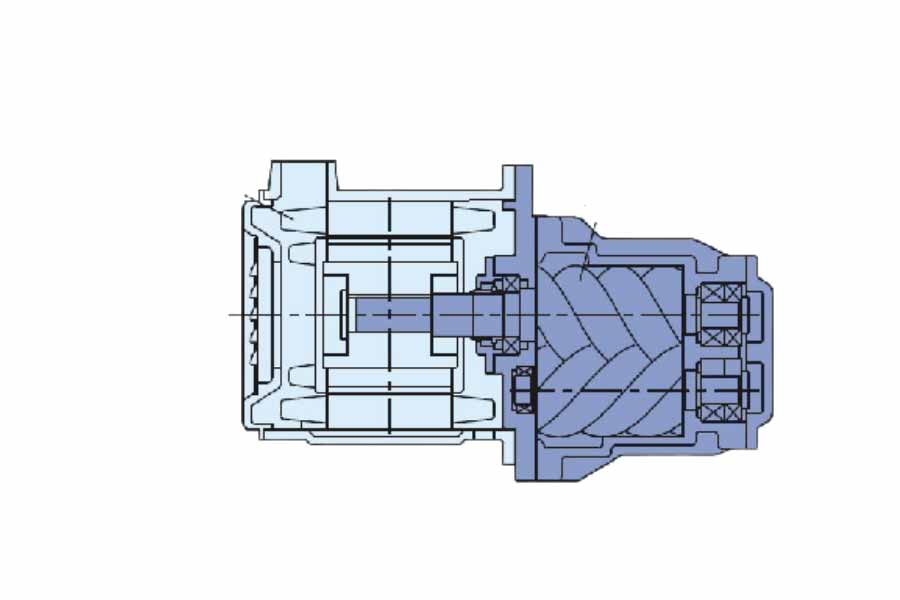

Two stage air compressor is to combine the first-stage compression rotor and the second-stage compression rotor in a casing and directly drive them through helical gears. Natural air enters the first stage of compression through the air filter, where it is mixed with a small amount of lubricating oil in the compression chamber, and the mixed air is compressed at the same time. The compressed air enters the cooling channel and comes into contact with a large amount of oil mist, thereby greatly reducing the temperature. The cooled compressed air enters the second-stage rotor, undergoes secondary compression, and is compressed to the final exhaust pressure.

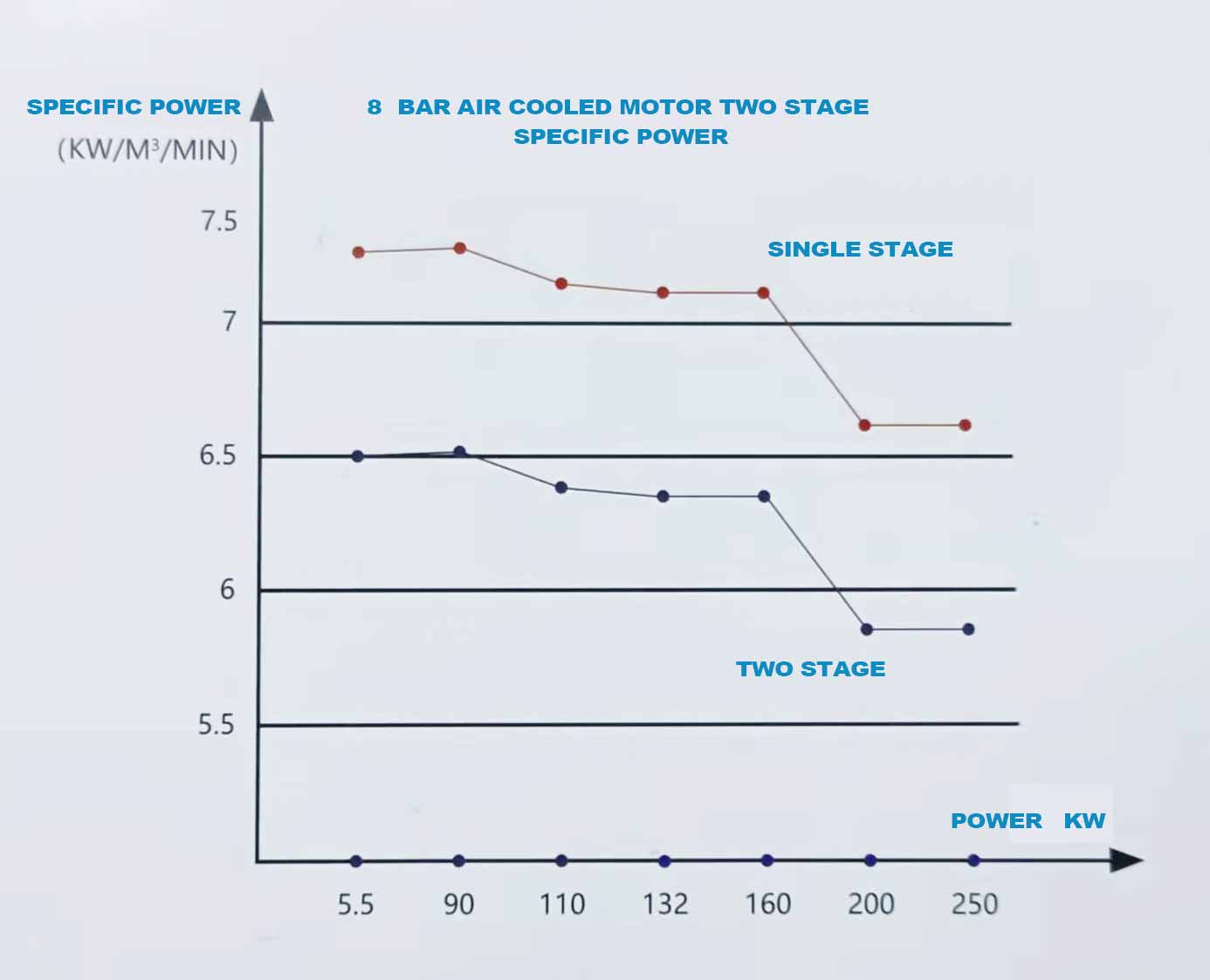

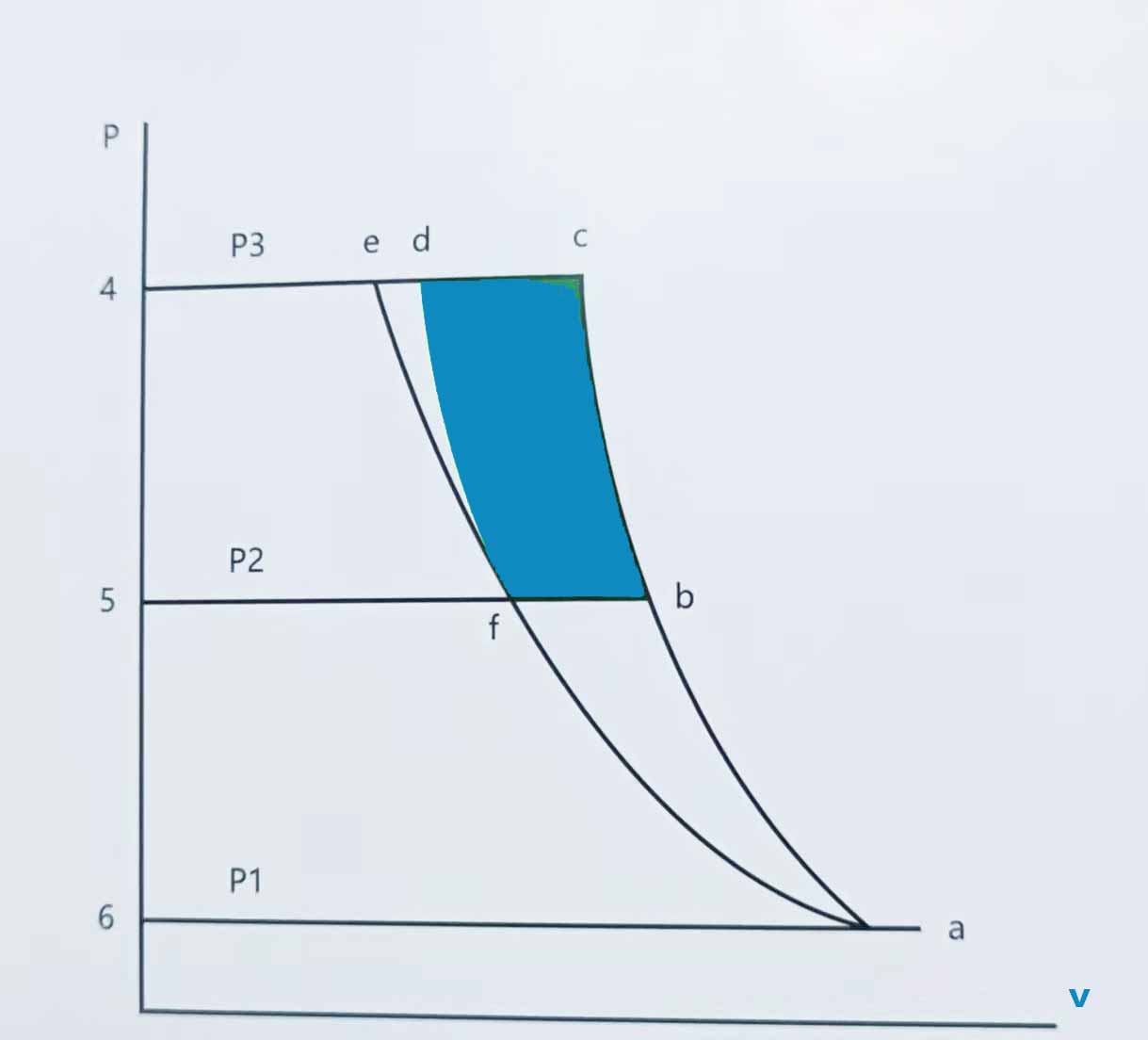

Two Stage air compressor is the isothermal compression.According to the theory of engineering thermodynamics, the isothermal compression is the most energy-saving for during the compression process. (When the temperature is high, the density of the air is lower, the more work is needed for compression). Not only that, isothermal compression can not only reduce the work consumed, but also reduce the temperature of the compressed air.